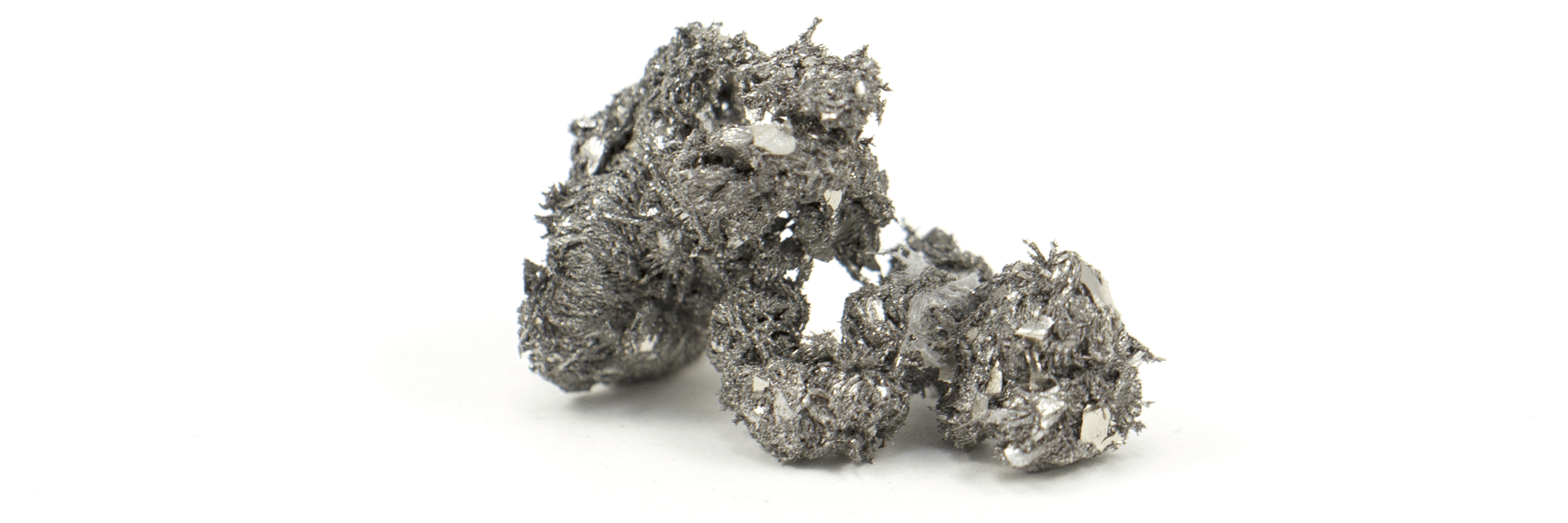

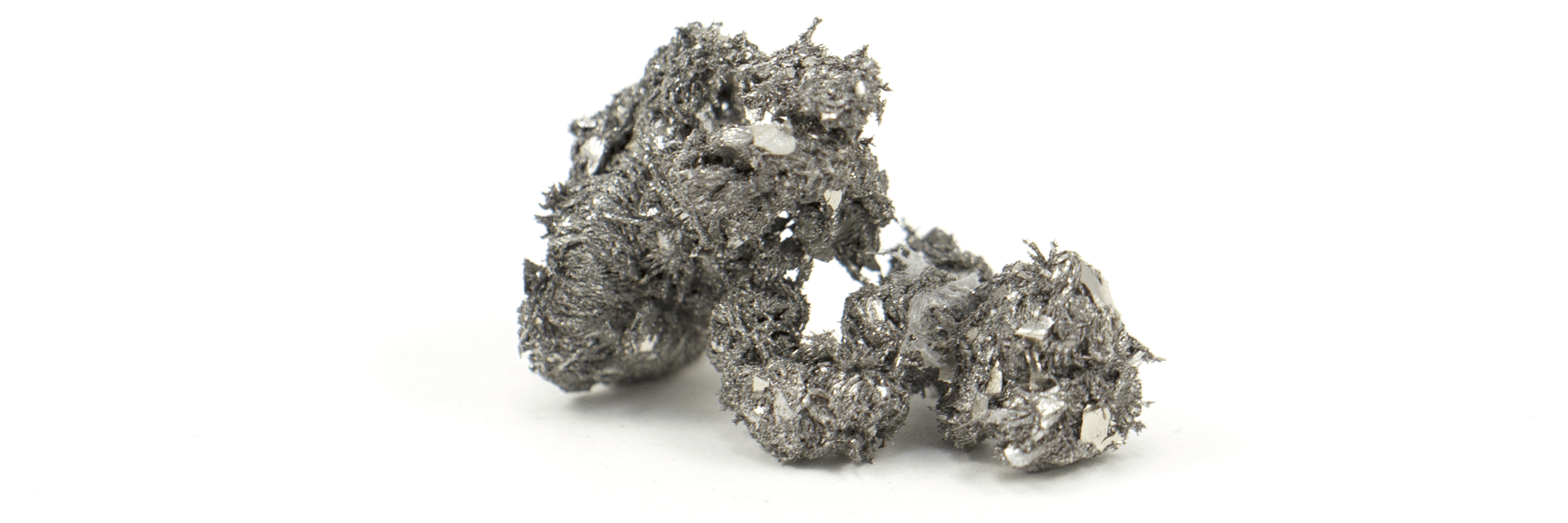

NEODYMIUM (NDFEB)

Neodymium (Nd) is a rare earth element with the atomic number 60 that was discovered in 1885 by Austrian chemist Carl Auer von Welsbach. Although part of the rare earth family neodymium is relatively abundant and is no rarer than copper.

Neodymium is mixed with iron and boron as well as traces of other elements such as dysprosium and praseodymium to produce a ferromagnetic alloy known as Nd2Fe14b, the strongest magnetic material in the world. Developed in 1982 by General Motors and Sumitomo Special Metals, neodymium magnets have replaced other types of magnetic materials in many modern commercial and industrial appliances.

Before neodymium can be made into neodymium magnets the mined rare earth mineral ore must be refined; a procedure involving dozens of chemical processes. Once refined, neodymium is mixed with iron, boron and other required elements to make the desired grade by heating them in a vacuum induction furnace until melted. Generally, the molten alloy is then cooled to form ingots before being ground into tiny grains in a jet mill.

The super-fine powder is then pressed in a mould while simultaneously being exposed to a large magnetic field produced by an electromagnet. As the powdered material is pressed the magnetic field aligns the individual magnetic domains of the ferromagnetic material in the direction of the magnetic field. As the material is pressed the direction is set and the anisotropic material is given its preferred direction of magnetism.

This preferred direction of magnetism contributes to the finished magnets strength and high coercivity. If there is no external magnetic field applied during this stage of the process the material’s individual magnetic domains will not all be uniformly aligned (isotropic) and as result, the material can be magnetised in any direction. However, the finished magnet will have a fraction of an anisotropic magnets strength and will have a lower coercivity.

Neodymium magnets are the strongest magnets available and therefore have a high power to volume and weight ratio. Because they are so strong it also means they have a relatively low cost per unit of strength (Maximum Energy Product, MGOe). They have an incredibly high resistance to being demagnetised but generally have low maximum operating temperatures compared to other materials and are susceptible to corrosion if their coating is damaged.

Other grades of neodymium magnet, including special high maximum operating temperature grades are available. For more information regarding the properties of grades not mentioned above, please refer to our neodymium magnet grades page.